Non Destructive Testing (NDT) techniques allow objects or materials to be examined without any residual damage. NDT provides cost-effective quality control and assurance, damage detection and risk mitigation at any stage of industrial production or service.

Q Tech NDT has extensive experience in developing testing programs for numerous machinery components with our NDT services both in the field and in the laboratory. We can identify flaws or inclusions in pieces before costly machining or service is required. Our team provides qualified and certified experts with the capability to choose the right NDT method to solve the inspection or testing challenge that any industrial project might face. With our state-of-the-art inspection technologies, you will save overall maintenance costs, improve production quality and ensure safe, reliable operating processes.

This technology enables efficient, high-precision detection of both surface and subsurface defects in welds through external X-ray or Gamma ray radiation. Our crawler-based ART solution ensures reliable and comprehensive weld inspections, helping to maintain pipeline integrity and compliance with industry standards, while minimizing operational downtime.

Gamma radiation provides high-resolution imaging of both surface and subsurface flaws, ensuring precise identification of any anomalies that could compromise the integrity of the pipeline. Combining gamma ray technology with our crawler systems allows for comprehensive and efficient inspection of welds in cross-country and CGD station piping works.

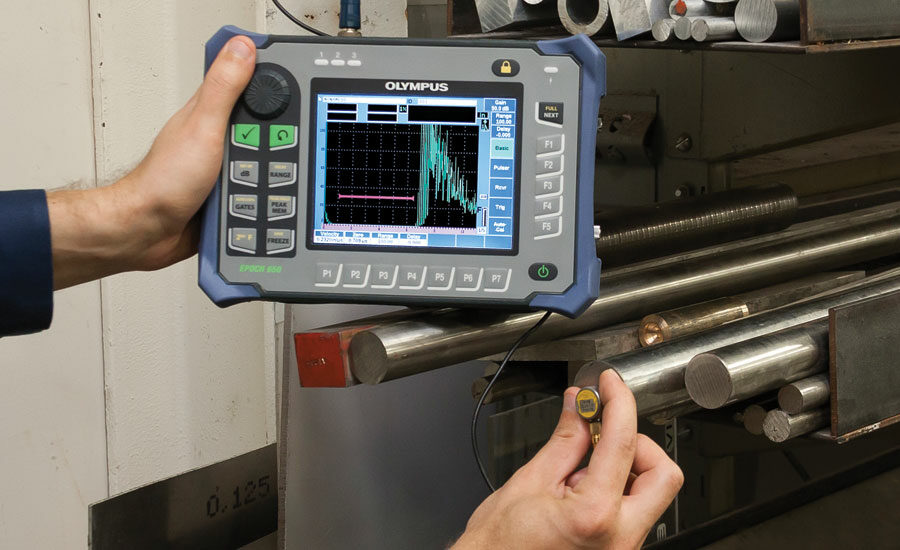

Ultrasonic methods of NDT employs the use of beams of sound waves (vibrations) of short wavelength and high frequency that is transmitted from a probe and detected by the same or other probes. Usually, pulsed beams of ultrasound are used and in the simplest instruments a single, handheld probe is placed on the specimen surface.

The height of the reflected pulse is related to the flaw size as seen from the transmitter probe. The relationship of flaw size, distance and reflectivity are complex, and a considerable skill is required to interpret the display.

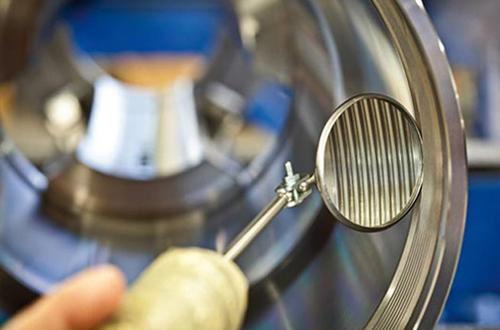

With the dye penetrant method, a penetrating liquid is applied to the surface of the component in order to enter the discontinuity or crack. Subsequently, after clearing the excess penetrant from the surface, the penetrant that exudes or is drawn back out of the crack, is observed.

Liquid penetrant testing is applied to any non-porous clean material, metallic or non-metallic, but is unsuitable for dirty or very rough surfaces. Penetrants can contain a dye to make the indication visible under white light, or a fluorescent material that fluoresces under the suitable ultra-violet light. Fluorescent penetrants are usually used when maximum flaw sensitivity is required.

The Magnetic Particle Inspection method of Non-Destructive testing is a used for locating surface and subsurface discontinuities in ferromagnetic material.

Depending on its operation on the face when the material or part under test is magnetized, discontinuities that lie in a direction generally transverse to the direction of the magnetic field. This causes a leakage field, and therefore, the presence of the discontinuity is detected by using finely divided ferromagnetic particles applied over the surface, some of these particles being gathered and held by the leakage field. This magnetically held collection of particles forms an outline of the discontinuity and indicates its location, size, shape and extent.

An array transducer is simply one that contains a number of separate elements in a single housing, and phasing refers to how those elements are sequentially pulsed. A phased array system is normally based around a specialized ultrasonic transducer that contains many individual elements (typically from 16 to 256) that can be pulsed separately in a programmed pattern. These transducers may be used with various types of wedges, in a contact mode, or in immersion testing.

Although time-of-flight diffraction (TOFD) can be used for a variety of applications, its primary use is rapid weld testing of circumferential and axial weld seams, also known as perpendicular TOFD scanning. Since the introduction of TOFD in the 1970s, the use of this reputed reliable non destructive testing technique has steadily increased. Manual execution is possible with TOFD, however, it is most commonly performed in combination with a recording device, that is, an encoder or industrial scanner. To achieve code compliance in North America, TOFD is often coupled with pulse-echo or phased array techniques in order to cover the root and cap regions of the weld.

DR is a form of X-ray imaging, where digital X-ray sensors are used instead of traditional photographic film. Advantages include time efficiency through bypassing chemical processing and the ability to digitally transfer and enhance images. Also, less radiation can be used to produce an image of similar contrast to conventional radiography.

Advanced NDT Solutions (ANS) continues to invest in the latest Technology with the addition of the Silverwing Computerised Magnetic Flux Leakage (MFL)Floormap 3D scanner with STARS technology to provide discrimination between top and bottom surface defects.Recent developments in the methods available to inspect tank floors make remaining life predictions easier. The Floormap3D is the most advanced MFL floor scanner on the market today. ANS combines this unit with a complimentary inspection tool (Hand Scan HS 100 system) that is ideal for the restricted areas such as adjacent to shell wall; below internal piping and at plate intersections; also for storage tanks of diameters lower than 10 m, petal floor plate designs or in situ heating coils.